Best practices

The impact of packaging on sustainability: A broad deep dive

Understanding packaging's environmental footprint: beyond surface-level insights

Packaging stands at the intersection of environmental responsibility, innovation, and strategic business growth. At Devera, we believe that every packaging decision has measurable consequences. This comprehensive guide explores the environmental implications of packaging choices, supported by science-backed data and actionable strategies that empower businesses to lead with sustainability.

A global perspective on packaging and the environment

The packaging industry is massive, not just economically, but environmentally. It generates more than $1 trillion annually and plays a key role in global emissions and waste. The rise of e-commerce and single-use culture has only intensified this impact. Plastic packaging alone contributes to nearly half of the world’s plastic waste, highlighting the urgent need for innovation and responsible decision-making.

To truly understand packaging’s footprint, companies must consider more than just materials. It's about the full lifecycle: from raw material extraction and manufacturing to logistics and end-of-life treatment.

Carbon footprint and material choices in packaging

Different packaging materials carry very different environmental costs. Traditional plastics, for example, emit around 2.7 kilograms of CO₂ per kilogram of material and can take up to 450 years to decompose. Beyond emissions, they also contribute significantly to microplastic pollution, an invisible but severe threat to ecosystems.

On the other hand, cardboard and paper-based packaging emit around 1.1 kg CO₂ per kg when made from virgin materials, and significantly less when recycled. Their renewable nature makes them a more sustainable option, although this depends heavily on responsible forestry practices.

Aluminum is another story. Producing virgin aluminum requires a high energy input -between 14 and 16 kWh per kilogram- and results in approximately 11.5 kg of CO₂ emissions. However, aluminum stands out for its recyclability: nearly 75% of all aluminum ever produced is still in use, and recycling it saves about 95% of the energy compared to producing it from scratch.

Designing better packaging with LCA

Life Cycle Assessment (LCA) is an essential tool in making packaging more sustainable. It enables businesses to assess the environmental impact of each stage in a product's life and compare different materials or design alternatives with precision. With LCA, we move from assumptions to measurable outcomes.

Companies aiming for circular packaging strategies should start by simplifying design. Mono-material formats are easier to recycle, and packaging designed for disassembly allows components to be separated and processed correctly. Reducing excess size or layers also cuts emissions from transport and raw material usage.

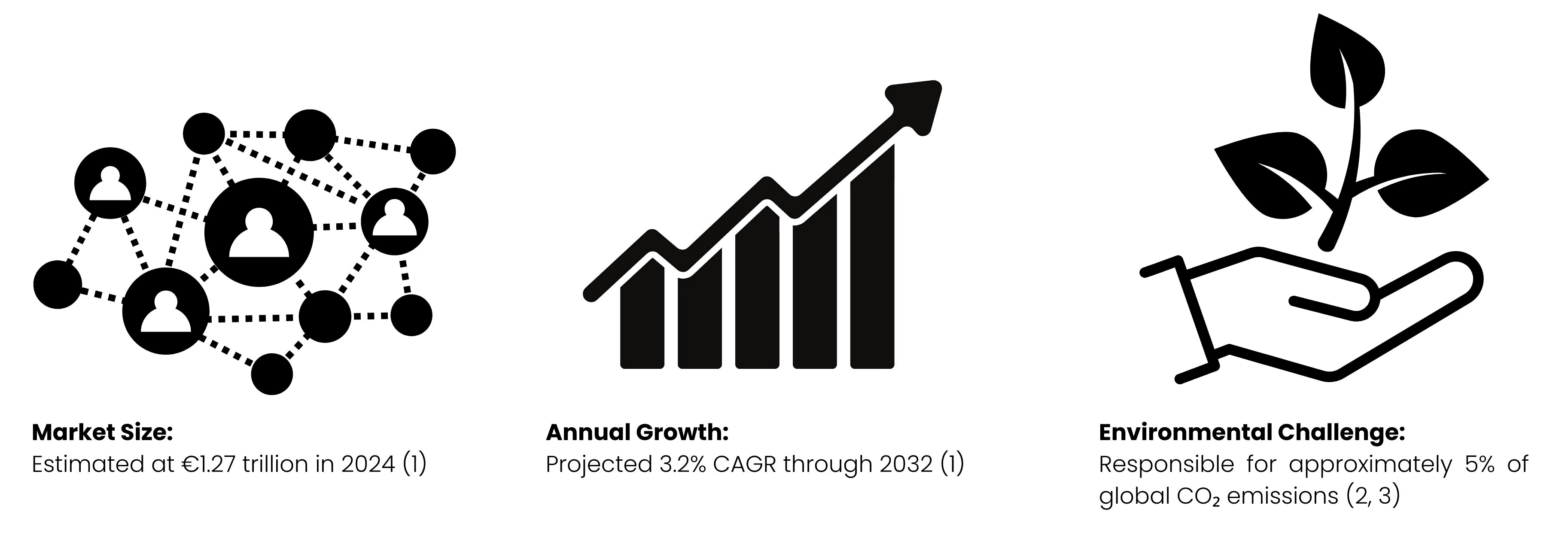

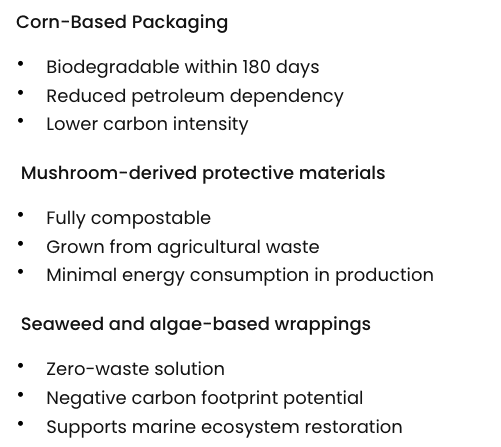

New materials, new possibilities for sustainable packaging

Biomaterials are reshaping how we think about packaging. For instance, packaging made from corn-based bioplastics can biodegrade in around 180 days and significantly reduce petroleum reliance. Similarly, mushroom-derived packaging offers full compostability and is grown from agricultural waste with minimal energy input. Innovations using seaweed and algae take it a step further—they are not only biodegradable but can potentially offer a negative carbon footprint while contributing to marine ecosystem restoration.

incluir tabla con los bullet points destacados

These innovations aren't just about replacing plastic, they represent a shift towards regenerative thinking in packaging design.

Closing the loop: recycling and recovery technologies

Advanced recycling methods are helping close the loop in packaging systems. Chemical recycling, for example, breaks down plastic polymers to their molecular base, allowing the creation of high-quality recycled materials indefinitely.

Closed-loop systems are also gaining traction, enabling the full recovery and reintegration of packaging materials into production cycles, which reduces dependency on virgin resources and minimizes waste.

Technology as a catalyst for smarter packaging

Emerging technologies are accelerating the shift to smarter, data-driven packaging solutions. Blockchain, for example, allows for full traceability of a product's packaging, from sourcing to carbon footprint, ensuring transparency and accountability across the supply chain.

Meanwhile, AI-driven design tools are changing the game. They can model packaging lifecycles, recommend optimal materials, and detect design inefficiencies before production begins. This allows businesses to make proactive, evidence-based decisions that reduce both environmental and financial risk.

At Devera, we integrate these technologies into our platform, making them accessible and scalable for any business ready to take sustainability seriously.

Regulations are changing… fast

Governments, particularly in the EU, are introducing strict regulations aimed at reducing packaging waste. By 2030, new directives will require at least 65% of packaging waste to be recycled, impose restrictions on single-use plastics, and mandate recycled content in packaging materials.

Additionally, the Product Environmental Footprint (PEF) standard will push companies to disclose environmental performance in a standardized and verifiable way.

These changes signal a move toward mandatory transparency, where sustainability claims will need to be backed by solid data and compliant with regulatory standards.

Sustainability as a business strategy

The shift toward sustainable packaging is no longer just an ethical choice, it’s a strategic one. Forecasts indicate that by 2025, over $350 billion will be invested in sustainable packaging solutions, and green packaging technologies are growing at a rate of 23% annually. Consumers are increasingly loyal to brands that show genuine commitment to environmental responsibility. In fact, recent studies show that people are three times more likely to trust brands with verified sustainability credentials.

Brands that embed sustainability into their packaging strategies position themselves as leaders, not just in compliance, but in innovation and customer trust.

Making the right choice: comparing packaging materials

Choosing the right material involves balancing environmental performance with function, cost, and availability. Here’s how some of the most common materials compare:

Virgin plastic has high emissions, low recyclability, and negligible biodegradability.

Recycled plastic performs moderately in all areas but depends on a well-functioning recycling system.

Cardboard is low in emissions, easily recyclable, and biodegradable, making it a solid all-rounder.

Bioplastics offer a very low carbon footprint and high biodegradability but are still limited in recyclability infrastructure.

Aluminum, while energy-intensive to produce, is highly recyclable and durable.

Understanding these trade-offs helps companies prioritize solutions that align with their sustainability goals and regional capabilities.

Smart tools for smarter decisions

With Devera’s emissions calculator, businesses can model the impact of their packaging decisions before making them. By inputting variables such as material type, transport distance, and end-of-life scenarios, teams can compare options and make data-driven choices.

This tool doesn’t just provide numbers, it supports better conversations between sustainability teams, designers, and decision-makers, ensuring that every change is meaningful and measurable.

Expert insights and future vision

"Sustainable packaging is not a cost—it's an investment in our planet's future and business resilience."

Dr. Elena Rodriguez, Global Sustainability Research Institute

At Devera, we simplify sustainability through smart tools, practical guidance, and real-time data. Whether you're evaluating your current packaging or designing a new product line, we help you:

Validate environmental claims to meet regulations

Identify opportunities for emissions reduction

Streamline collaboration between sustainability, compliance, and design teams

If your business is ready to move from assumptions to action, Devera is here to support your transition.

Understanding packaging's environmental footprint: beyond surface-level insights

Packaging stands at the intersection of environmental responsibility, innovation, and strategic business growth. At Devera, we believe that every packaging decision has measurable consequences. This comprehensive guide explores the environmental implications of packaging choices, supported by science-backed data and actionable strategies that empower businesses to lead with sustainability.

A global perspective on packaging and the environment

The packaging industry is massive, not just economically, but environmentally. It generates more than $1 trillion annually and plays a key role in global emissions and waste. The rise of e-commerce and single-use culture has only intensified this impact. Plastic packaging alone contributes to nearly half of the world’s plastic waste, highlighting the urgent need for innovation and responsible decision-making.

To truly understand packaging’s footprint, companies must consider more than just materials. It's about the full lifecycle: from raw material extraction and manufacturing to logistics and end-of-life treatment.

Carbon footprint and material choices in packaging

Different packaging materials carry very different environmental costs. Traditional plastics, for example, emit around 2.7 kilograms of CO₂ per kilogram of material and can take up to 450 years to decompose. Beyond emissions, they also contribute significantly to microplastic pollution, an invisible but severe threat to ecosystems.

On the other hand, cardboard and paper-based packaging emit around 1.1 kg CO₂ per kg when made from virgin materials, and significantly less when recycled. Their renewable nature makes them a more sustainable option, although this depends heavily on responsible forestry practices.

Aluminum is another story. Producing virgin aluminum requires a high energy input -between 14 and 16 kWh per kilogram- and results in approximately 11.5 kg of CO₂ emissions. However, aluminum stands out for its recyclability: nearly 75% of all aluminum ever produced is still in use, and recycling it saves about 95% of the energy compared to producing it from scratch.

Designing better packaging with LCA

Life Cycle Assessment (LCA) is an essential tool in making packaging more sustainable. It enables businesses to assess the environmental impact of each stage in a product's life and compare different materials or design alternatives with precision. With LCA, we move from assumptions to measurable outcomes.

Companies aiming for circular packaging strategies should start by simplifying design. Mono-material formats are easier to recycle, and packaging designed for disassembly allows components to be separated and processed correctly. Reducing excess size or layers also cuts emissions from transport and raw material usage.

New materials, new possibilities for sustainable packaging

Biomaterials are reshaping how we think about packaging. For instance, packaging made from corn-based bioplastics can biodegrade in around 180 days and significantly reduce petroleum reliance. Similarly, mushroom-derived packaging offers full compostability and is grown from agricultural waste with minimal energy input. Innovations using seaweed and algae take it a step further—they are not only biodegradable but can potentially offer a negative carbon footprint while contributing to marine ecosystem restoration.

incluir tabla con los bullet points destacados

These innovations aren't just about replacing plastic, they represent a shift towards regenerative thinking in packaging design.

Closing the loop: recycling and recovery technologies

Advanced recycling methods are helping close the loop in packaging systems. Chemical recycling, for example, breaks down plastic polymers to their molecular base, allowing the creation of high-quality recycled materials indefinitely.

Closed-loop systems are also gaining traction, enabling the full recovery and reintegration of packaging materials into production cycles, which reduces dependency on virgin resources and minimizes waste.

Technology as a catalyst for smarter packaging

Emerging technologies are accelerating the shift to smarter, data-driven packaging solutions. Blockchain, for example, allows for full traceability of a product's packaging, from sourcing to carbon footprint, ensuring transparency and accountability across the supply chain.

Meanwhile, AI-driven design tools are changing the game. They can model packaging lifecycles, recommend optimal materials, and detect design inefficiencies before production begins. This allows businesses to make proactive, evidence-based decisions that reduce both environmental and financial risk.

At Devera, we integrate these technologies into our platform, making them accessible and scalable for any business ready to take sustainability seriously.

Regulations are changing… fast

Governments, particularly in the EU, are introducing strict regulations aimed at reducing packaging waste. By 2030, new directives will require at least 65% of packaging waste to be recycled, impose restrictions on single-use plastics, and mandate recycled content in packaging materials.

Additionally, the Product Environmental Footprint (PEF) standard will push companies to disclose environmental performance in a standardized and verifiable way.

These changes signal a move toward mandatory transparency, where sustainability claims will need to be backed by solid data and compliant with regulatory standards.

Sustainability as a business strategy

The shift toward sustainable packaging is no longer just an ethical choice, it’s a strategic one. Forecasts indicate that by 2025, over $350 billion will be invested in sustainable packaging solutions, and green packaging technologies are growing at a rate of 23% annually. Consumers are increasingly loyal to brands that show genuine commitment to environmental responsibility. In fact, recent studies show that people are three times more likely to trust brands with verified sustainability credentials.

Brands that embed sustainability into their packaging strategies position themselves as leaders, not just in compliance, but in innovation and customer trust.

Making the right choice: comparing packaging materials

Choosing the right material involves balancing environmental performance with function, cost, and availability. Here’s how some of the most common materials compare:

Virgin plastic has high emissions, low recyclability, and negligible biodegradability.

Recycled plastic performs moderately in all areas but depends on a well-functioning recycling system.

Cardboard is low in emissions, easily recyclable, and biodegradable, making it a solid all-rounder.

Bioplastics offer a very low carbon footprint and high biodegradability but are still limited in recyclability infrastructure.

Aluminum, while energy-intensive to produce, is highly recyclable and durable.

Understanding these trade-offs helps companies prioritize solutions that align with their sustainability goals and regional capabilities.

Smart tools for smarter decisions

With Devera’s emissions calculator, businesses can model the impact of their packaging decisions before making them. By inputting variables such as material type, transport distance, and end-of-life scenarios, teams can compare options and make data-driven choices.

This tool doesn’t just provide numbers, it supports better conversations between sustainability teams, designers, and decision-makers, ensuring that every change is meaningful and measurable.

Expert insights and future vision

"Sustainable packaging is not a cost—it's an investment in our planet's future and business resilience."

Dr. Elena Rodriguez, Global Sustainability Research Institute

At Devera, we simplify sustainability through smart tools, practical guidance, and real-time data. Whether you're evaluating your current packaging or designing a new product line, we help you:

Validate environmental claims to meet regulations

Identify opportunities for emissions reduction

Streamline collaboration between sustainability, compliance, and design teams

If your business is ready to move from assumptions to action, Devera is here to support your transition.